Introduction

Materials and Methods

Plant Materials

Measurement of Fruit Quality Attributes

Statistical Analysis

Results and Discussion

Introduction

Hardy kiwifruit (Actinidia arguta) is one of the most recently domesticated fruit species and has displayed increased consumer preference owing to its highly aromatic flavor and well-balanced sweet and sour taste (Fisk et al., 2006; Oh et al., 2014; Oh et al., 2017). The fruit have an edible skin and are smaller than those of the fuzzy kiwifruit (A. deliciosa); they are considered a health-promoting food because they have high levels of vitamin C, phenolic compounds, lutein, and minerals such as Ca, Fe, P, and Zn (Krupa et al., 2011; Latocha et al., 2011).

The advantages of cultivating hardy kiwifruit are its cold tolerance (down to ‑ 30ºC in midwinter) and its relatively short vegetation period of about 150 d compared to that of A. deliciosa, which lasts about 220 ‑ 224 d. Therefore, hardy kiwifruit can be cultivated commercially in regions with colder climates that are unsuitable for A. deliciosa cultivation (Okamoto and Goto, 2005; Krupa et al., 2011). In recent years, hardy kiwifruit has started to be grown in Chile, Japan, Korea, New Zealand, certain European countries, and the USA (Williams et al., 2002; Okamoto and Goto, 2005; Krupa et al., 2011; Oh et al., 2017). In South Korea, hardy kiwifruit is mainly grown in the mountains and valleys below an altitude of about 1,000 m above sea level (Jung et al., 2016). New cultivars of hardy kiwifruit, such as ‘Cheongsan’, ‘Daeseong’, ‘Saehan’, ‘Chilbo’, ‘Autumn Sense’, and ‘Mansu’, have been developed and are cultivated in Korea (Kim et al., 2014; Oh et al., 2014; Jung et al., 2016; Lim et al., 2016).

Soluble solids content (SSC) is a commonly used index for hardy kiwifruit maturity. The fruit have approximately 18 ‑ 25% SSC when ripe on the vine. However, to increase shelf life and facilitate harvest, hardy kiwifruit is harvested between 8 and 14% SSC, when the fruit are still firm. Aroma and flavor of hardy kiwifruit are maximized when they are ripened on the vine, but the shelf life of the fruit is shortened (Strik, 2005). Thus, the fruit are commonly harvested before ripening because they are too soft to package when fully ripe (Strik, 2005; Fisk et al., 2006; Krupa et al., 2011). Hardy kiwifruits are ripened under refrigeration, a common practice for green flesh kiwifruit, which can be harvested when the SSC is approximately 6.5% (Strik and Hummer, 2006).

Harvest maturity and storage conditions (shelf life vs. cold storage) could affect the physiological and sensory characteristics of hardy kiwifruit. A previous study demonstrated that cold storage decreased firmness, sour taste, and titratable acidity (TA) and increased the overall intensity of the aroma, content of total phenolic compounds (TPC), and sweet taste of ripened ‘Ananasnaya’ hardy kiwifruit compared to shelf life (Fisk et al., 2006; Cha et al., 2019). Krupa et al. (2011) reported that ‘Weiki’ and ‘74 ‑ 49’ hardy kiwifruit cultivars stored at 1ºC for 42 d showed significant similarities with vine-ripened fruit in the physicochemical characteristics examined (i.e., an increase in SSC, with decrease in ascorbic acid content, firmness, TA, and TPC). TA values of cold stored fruit actually decreased below the levels of vine-ripened fruit.

For commercial distribution in Korea, the suggested storage period of hardy kiwifruit is 1 ‑ 2 weeks, with an additional 2 ‑ 3 d for shelf life. Short shelf life of the fruit is mainly the result of fruit softening, shriveling due to dryness, fungal development, and subsequent decay (Krupa et al., 2011; Lim et al., 2016). In a recent study on cultivation and morphological characteristics, new cultivars of hardy kiwifruit were examined, including ‘Chilbo’, ‘Daeseong’, and ‘Saehan’ (Kim et al., 2014). However, there is little information on their postharvest characteristics and what postharvest treatments and storage conditions are required to improve their short storability and marketability.

Here, we determined the postharvest characteristics of ‘Cheongsan’, the most commonly cultivated kiwifruit in Korea, as well as ‘Daebo’ and ‘Daeseong’, which are newly developed hardy kiwifruits. Additionally, we monitored quality changes and physiological disorders during shelf life and cold storage. Thus, this study will provide basic information on the physiological responses of postharvest fruit quality during shelf life and cold storage, which will be helpful for further studies on postharvest handling and extending the shelf life of this fruit.

Materials and Methods

Plant Materials

Hardy kiwifruit (Actinidia arguta) cultivars ‘Cheongsan’ and ‘Daebo’ were grown in Wonju, Gangwon-do, Korea (37º45' N, 127º89' E), and ‘Daeseong’ was grown in Gwangyang, Jeollanam-do, Korea (35º30' N, 127º59' E). All the hardy kiwifruit trees in both Wonju and Gwangyang were cultivated in fields with pergola trellis systems, and the fruit were harvested from 5-year-old trees that had similar levels of tree vigor. Nutrients and water were supplied using the fertigation system, which is commonly used at the Korea Forest Research Institute (http://know.nifos.go.kr/book/index.ax). All of the hardy kiwifruits were hand-harvested in the early morning at a practical harvest maturity based on an SSC of about 6% (Fig. 1) and transported to the laboratory. ‘Cheongsan’, Daebo’, and ‘Daeseong’ fruits were harvested on August 29, 2018, September 10, 2018, and September 12, 2018, respectively, and fruit were chosen based on their uniform size, appearance, and lack of visible defects. The selected fruit were randomly packed in low-vent plastic containers (179 × 132 × 78 mm, Easepack, Seoul, Korea) with approximately 200 g of fruit per container. They were stored at 22 ± 1ºC for 1 week and at 2 ± 1ºC for 10 weeks. During storage, 12 fruit each were taken from three plastic containers after 0, 1, 2, 3, 5, and 7 d at 22ºC for shelf life and after 0, 1, 2, 3, 4, 5, 7, and 10 weeks at 2ºC for cold storage.

Fig. 1.

Hardy kiwifruit (Actinidia arguta) cultivars ‘Cheongsan’ (A), ‘Daebo’ (B), and ‘Daeseong’ (C) at harvest. All the hardy kiwifruit trees were cultivated in a field with pergola trellis systems, and the fruits were harvested from 5-year-old trees that showed similar levels of tree vigor. All hardy kiwifruit were hand-harvested in the early morning at a practical harvest maturity based on an SSC of about 6%.

Measurement of Fruit Quality Attributes

Weight loss was evaluated in 10 replicates by weighing each hardy kiwifruit and is presented as the percentage of weight at each sampling time relative to the initial weight immediately after packaging. The respiration rate was determined using a headspace gas analyzer (CheckMate 3; Dansensor MOCON, Ringsted, Denmark). For each of five replicates, 10 fruit were randomly chosen and placed in a 250-mL sealed jar with a septum in the lid. After 1 hour, a headspace gas sample was collected through the septum and immediately injected into the gas analyzer. The respiration rate of the samples was expressed in mg CO2·kg-1·h-1.

Firmness was measured using a texture analyzer (CR-3000EX-S; Sun Scientific, Tokyo, Japan) equipped with a 5-mm-diameter punch probe. Each fruit was subjected to a compression speed of 250 mm·min-1 after contact and penetration to 10 mm, at approximately the center of the flat surface of the fruit. The results are presented as the mean maximum peak force from 36 replicates and expressed in newton (N).

Marketability was determined by a visual assessment of 10 individual fruit by observing symptoms of physiological processes associated with aging of fruit, specifically, decay, shriveling, and pitting. The incidences of decay, shriveling, and pitting were evaluated on a 5-point Likert scale, where 0 = 0%, 1 = 1 ‑ 10%, 2 = 11 ‑ 25%, 3 = 26 ‑ 50%, 4 = 51 ‑ 75%, and 5 = 76 ‑ 100% of the area of the fruit affected. Overall marketability was calculated as follows: 15 - (sum of the three index scores).

SSC and TA were measured using a combined extract from four fruits from each of three containers, with nine replicates. A refractometer (PR-101α; ATAGO, Tokyo, Japan) was used to measure the SSC in the juices squeezed, and the results are expressed as a percentage. TA was determined with a TA meter (GMK-835N; G-Won Hitech, Seoul, Korea) and is expressed using percentage anhydrous citric acid as the reference (Marsh et al., 2004).

Statistical Analysis

The experiment had a completely randomized design with the three cultivars and two storage conditions with replicates. All experimental data are presented as the mean of the replicates followed by the standard error. To compare the two storage conditions and the three cultivars, analysis of variance (ANOVA) tests were performed, followed by Tukey’s multiple range tests, with the significant level set at p < 0.05. Statistics were determined using SPSS Statistics version 18.0 (SPSS Inc., Chicago, IL, USA). To elucidate the overall response of the postharvest qualities, we created heatmap using mean and standard deviation of normalized values using SPSS software. After transformation of all the data sets, the lowest and highest values were ‑ 1.92 and 3.54. Normalized values were used with the color scale system from Microsoft Office Excel 2016 (Microsoft Corporation, Redmond, WA, USA) to generate heatmap. Pearson’s correlation analysis was performed using SPSS to determine the strength of the relationships between evaluation indexes of the three cultivars of hardy kiwifruit.

Results and Discussion

The fresh weight of ‘Daebo’ (20.8 g) was approximately two times that of ‘Cheongsan’ (10.9 g) and ‘Daeseong’ (11.0 g). Furthermore, the ranking of the dry weights showed the same pattern: ‘Daebo’ (3.8 g), ‘Daeseong’ (1.8 g), and ‘Cheongsan’ (1.7 g). The SSC and TA of the fruit of the three cultivars at harvest were observed to be at similar levels of 5.8 ‑ 6.6% and 1.0 ‑ 1.2%, respectively.

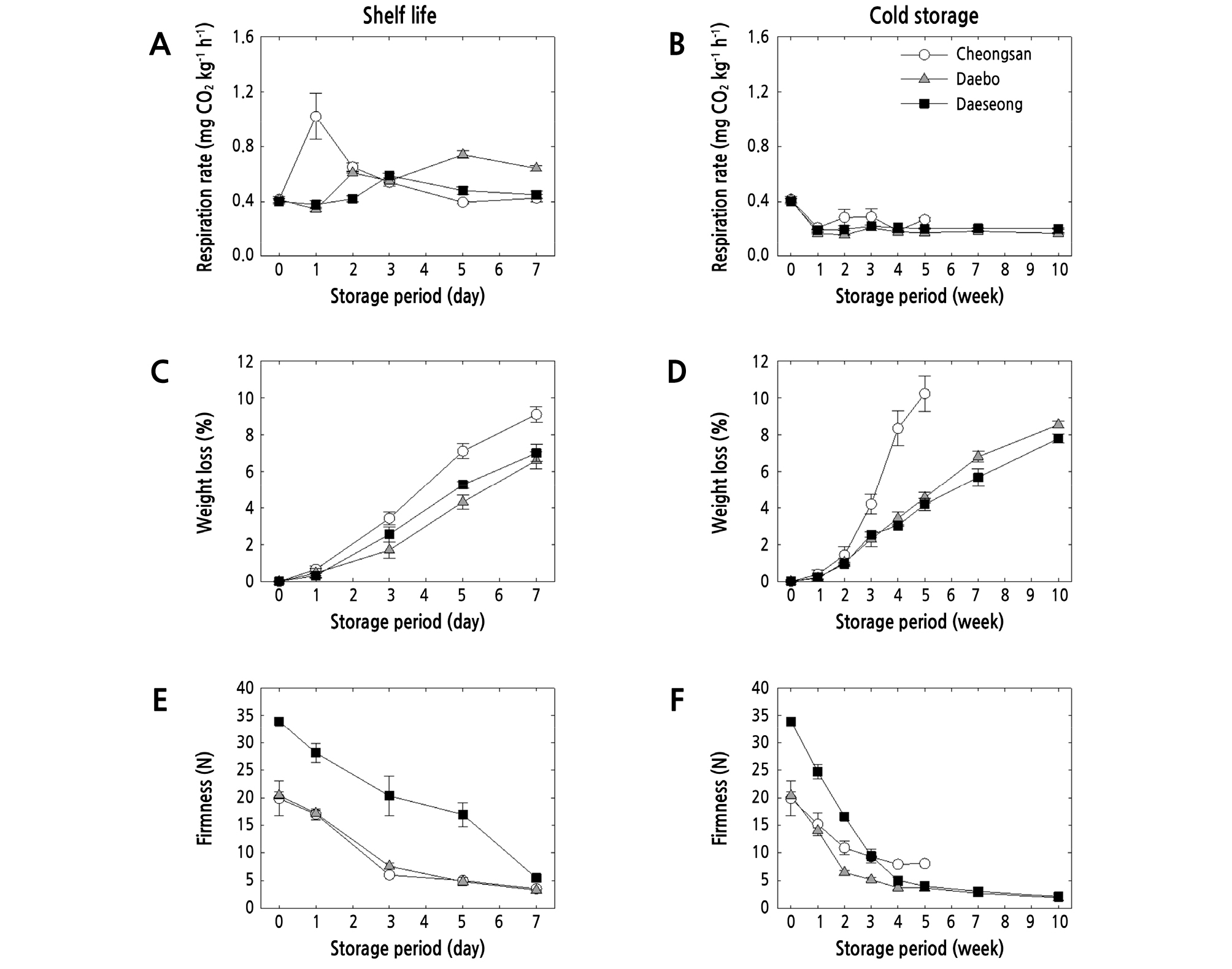

We observed that the respiration rates at harvest were at similar levels, 0.4 mg CO2·kg-1·h-1, in the three cultivars studied; subsequently, they were significantly higher in the fruit stored in shelf life than those during cold storage (Fig. 2A and 2B). During shelf life at 22ºC, the respiration rates of the fruits gradually increased after harvest; the highest respiration rate was observed on days 1, 3, and 5 of shelf life in ‘Cheongsan’ (1.0 mg CO2·kg-1·h-1), ‘Daeseong’ (0.6 mg CO2·kg-1·h-1), and ‘Daebo’ (0.7 mg CO2·kg-1·h-1), respectively. Subsequently, the respiration rate in the three cultivars decreased over the 7-d storage period. Conversely, the respiration rates in the fruit of the three cultivars were suppressed to 0.2 ‑ 0.3 mg CO2·kg-1·h-1 after 1 week of cold storage. We found that the respiration rate of all three cultivars of the hardy kiwifruit peaked shortly after initiating storage at 22ºC. Additionally, ‘Cheongsan’ showed the highest respiration rate compared to ‘Daebo’ and ‘Daeseong’. According to Wang et al. (2015), hardy kiwifruits display typical climacteric characteristics, and the respiration rates of climacteric fruits are highly correlated with their ethylene production rates during storage. For this reason, further studies of ethylene analysis in ‘Cheongsan’, Daebo’, and ‘Daeseong’ hardy kiwifruit during storage are needed to compare the physicochemical characteristics of the different cultivars.

Fig. 2.

Change in the respiration rate (A and B), weight loss (C and D), and firmness (E and F) in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit during storage at 22°C for up to 7 d during shelf life (A, C, and E) and 2°C for up to 10 weeks during cold storage (B, D, and F). Values represent the mean ± standard errors of replicates (n = 5 for respiration rate, n = 10 for weight loss, and n = 36 for firmness).

The main factor responsible for the deterioration of stored hardy kiwifruit was rapid softening owing to water loss and decay. Thus, weight loss and fruit firmness were essential parameters for determining fruit storability (Wang et al., 2015). The rate of weight loss gradually increased both during shelf life and cold storage (Fig. 2C and 2D). The highest weight loss was found in ‘Cheongsan’ fruit during storage, with values of up to 7.0% after 5 d of shelf life and 4 weeks in cold storage. However, ‘Daebo’ and ‘Daeseong’ fruits showed a low rate of weight loss compared to ‘Cheongsan’ fruits during the entire storage period, and there was no significant difference between ‘Daebo’ and ‘Daeseong’. ‘Daeseong’ fruit exhibited relatively high firmness compared to ‘Cheongsan’ and ‘Daebo’ fruit, and the fruit firmness consistently decreased during shelf life and cold storage (Fig. 2E and 2F). The firmness rapidly declined to about 6.0 N after 3, 5, and 7 d of shelf life in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’, respectively. On the other hand, cold storage delayed fruit softening in the three cultivars. The firmness of ‘Cheongsan’ during cold storage decreased from 19.9 N at harvest to 10.9 N at 2 weeks in storage, and this value was maintained until 5 weeks in storage. ‘Daebo’ showed a 68.1% decline in fruit firmness after 2 weeks in cold storage compared to its initial level, and its firmness steadily decreased to 6.0 N after 3 weeks in cold storage. ‘Cheongsan’ showed high respiration rates and weight loss and low firmness compared to ‘Daeseong’, regardless of storage temperature. According to the Korea Meteorological Administration (http://www.kma.go.kr), the temperature in August of 2018 was relatively hotter than September of 2018. In a previous study, weather conditions during the fruit ripening phase were strongly correlated with A. arguta fruit quality (Moretti et al., 2010). Thus, it may be assumed that deterioration of stored ‘Cheongsan’, which is an early-season hardy kiwifruit variety, may be greatly influenced by high temperatures during growth and harvest time compared to a late-season hardy kiwifruit, such as ‘Daeseong’. Our firmness results were similar to those reported from ‘Ananasnaya’ hardy kiwifruit, which shows a rapid decrease in firmness in the first weeks of storage at room temperature (Fisk et al., 2008). However, cold storage at 1ºC with 1-methylcyclopropene (1-MCP) treatment delayed softening in ‘Cheongsan’ fruit (Lim et al., 2016). White et al. (2005) reported that the fruit softening rates vary with species of Actinidia. The difference in fruit softening between different genotypes has been associated with the final firmness of fully ripened fruit (White et al., 2005; Shin et al., 2018, Shin et al., 2019). ‘Daeseong’ is a late-season hardy kiwifruit cultivar; hence, its fruits tend to lose firmness at a slower rate than the early-season cultivar ‘Cheongsan’ due to genetic differences. Furthermore, large-fruited species tend to be relatively softer than small-fruited species even towards the end of the ripening process (White et al., 2005). Thus, the rapid softening observed in ‘Daebo’ during cold storage might be why its fruits are larger than ‘Cheongsan’ and ‘Daeseong’.

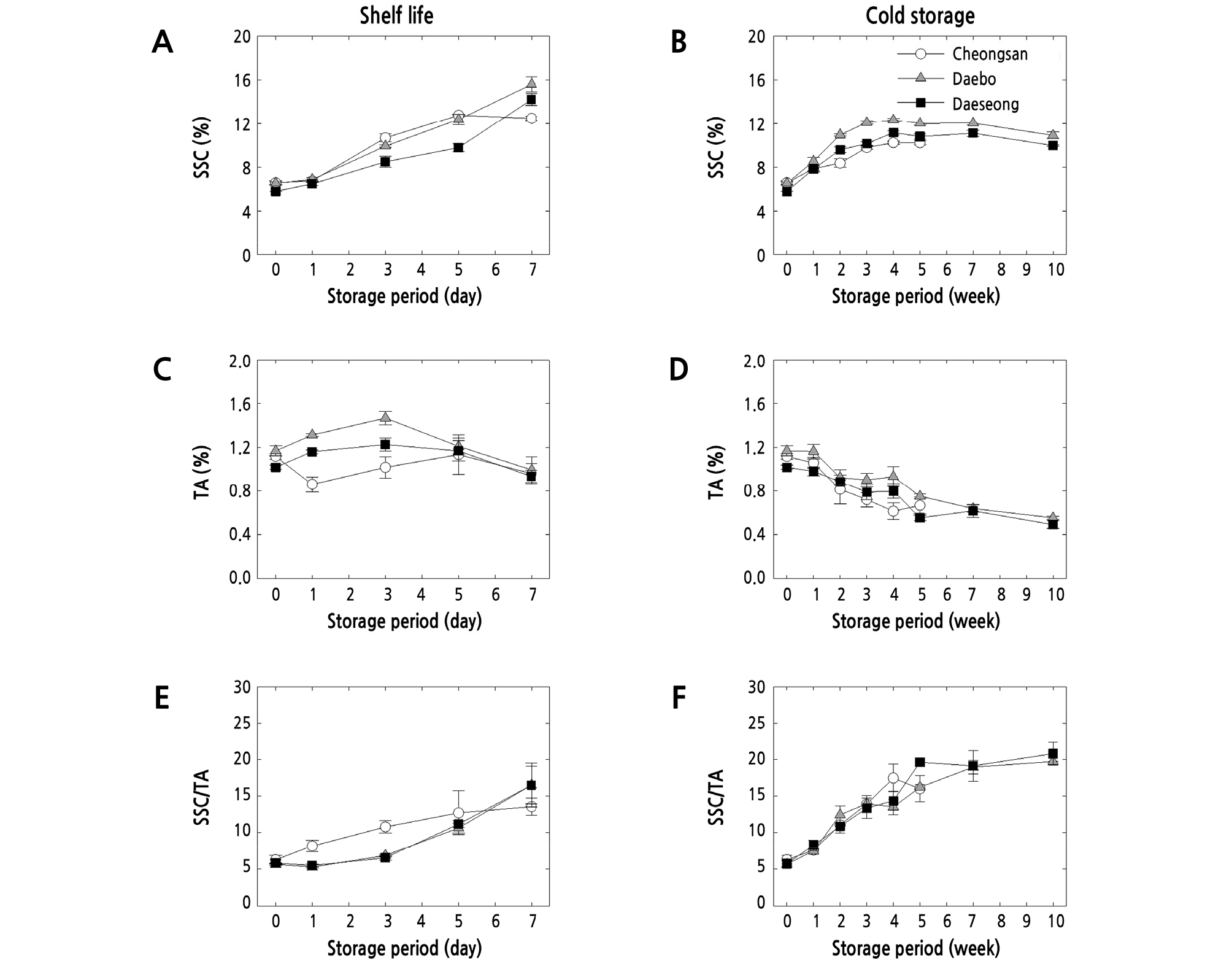

The SSC, TA, and SSC and TA ratio are important indices determining the taste and consumer acceptability of hardy kiwifruit (Fisk et al., 2006). The SSC of ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ fruit increased 1.9 (12.5%), 2.4 (15.6%), and 2.4 (14.2%) times, respectively, at the end of shelf life, compared with their initial SSC (Fig. 3A). In cold storage, the SSC also gradually increased in the fruits of the three cultivars for 3 weeks in storage and then its levels were maintained until the end of storage at approximately 10.1, 11.9, and 10.6% in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’, respectively (Fig. 3B). The fruits in cold storage showed relatively lower SSC values than those during shelf life throughout the storage period. The TA detected in the fruits of the three cultivars was unstable during shelf life (Fig. 3C). On the other hand, TA slightly decreased to 40.2, 53.0, and 52.0% in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ fruit, respectively, by the end of cold storage compared to their initial levels (Fig. 3D). The SSC and TA ratio increased during storage regardless of fruit cultivar and storage regime (Fig. 3E and 3F). At the end of storage, their ratios in fruit stored in cold storage were relatively higher (16.0, 19.7, and 20.8 in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong, respectively) than during shelf life (13.5, 16.5, and 15.6 in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong, respectively) because the fruit stored in the cold exhibited a rapid decline in TA, although they had relatively lower SSC values than the fruit stored on the shelf. The increase of SSC and decrease of TA in hardy kiwifruit during storage observed in this study are consistent with previous reports. SSC increased by approximately 1.8 ‑ 2.0 times and 1.5 ‑ 1.8 times compared to initial levels in ‘Ananasnaya’ and ‘Biongo’ cultivars, respectively, after 8 weeks of storage at cold temperatures (Fisk et al., 2006; Krupa et al., 2011; Latocha et al., 2014).

Fig. 3.

Change in the soluble solids content (SSC) (A and B), titratable acidity (TA) (C and D), and ratio of SSC to TA (E and F) in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit stored at 22°C for up to 7 d during shelf life (A, C, and E) and 2°C for up to 10 weeks during cold storage (B, D, and F). Values represent the mean ± standard errors of replicates (n = 9).

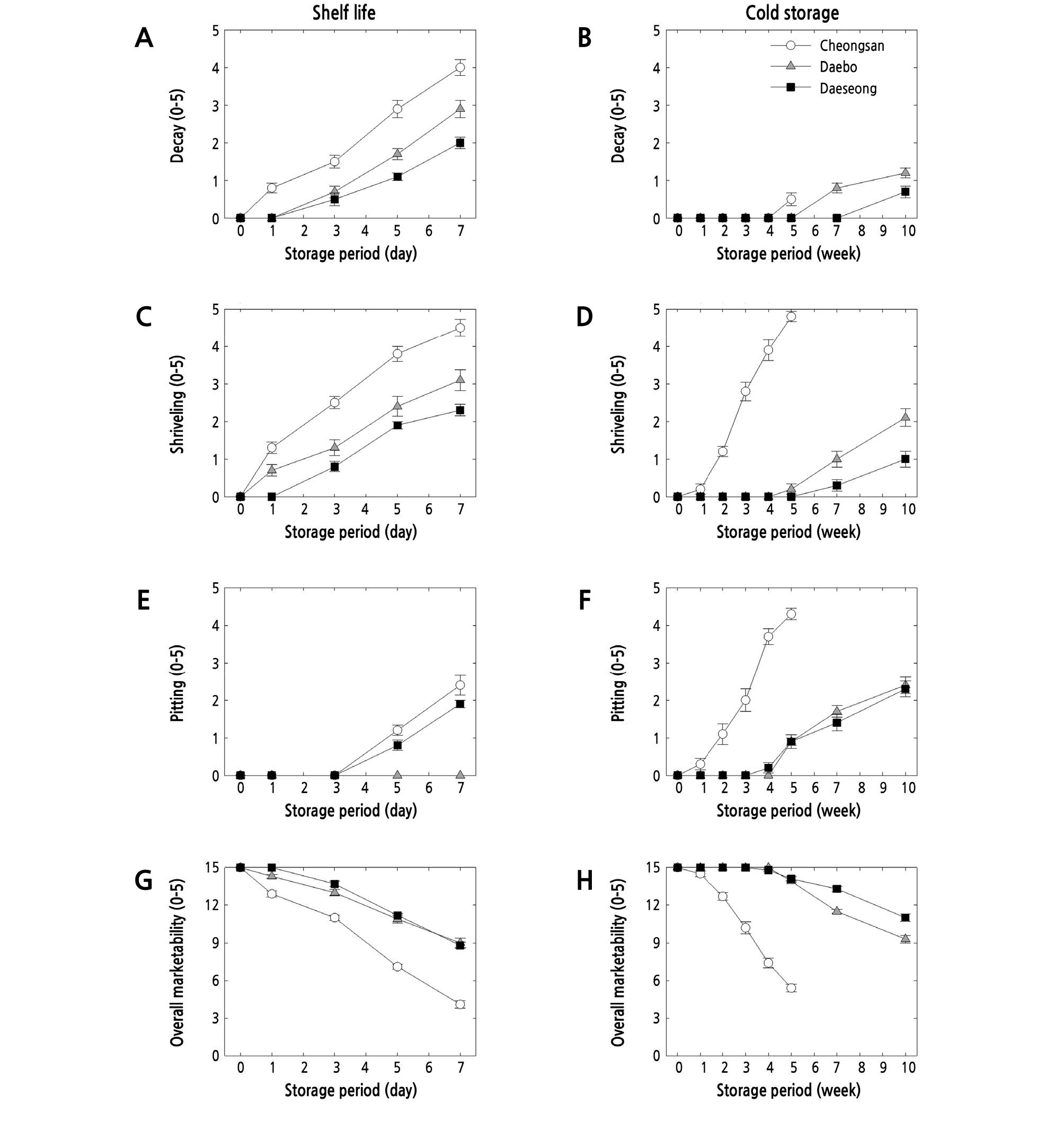

With increasing storage duration, physiological disorders such as decay, shriveling, and pitting were visually apparent. The incidence rates of decay and fruit shriveling were significantly higher in ‘Cheongsan’ fruit, followed by ‘Daebo’ and ‘Daeseong’ during shelf life (Fig. 4A and 4C). Pitting on the surface of fruit appeared after 5 d of shelf life in ‘Cheongsan’ and ‘Daeseong’, and pitting was not observed in ‘Daebo’ fruit (Fig. 4E). Development of fungal decay did not occur in the fruits of the three cultivars until 4 weeks in cold storage, and even then, the rate was less than 10% by the end of the storage period (Fig. 4B). ‘Cheongsan’ exhibited the highest score for shriveling during cold storage (Fig. 4D). Conversely, ‘Daebo’ and ‘Daeseong’ significantly delayed fruit shriveling, and similar results were found for pitting (Fig. 4F). Consequentially, ‘Cheongsan’ fruits had a lower overall marketability regardless of storage temperature compared to ‘Daebo’ and ‘Daeseong’ fruit (Fig. 4G and 4H). The main factors causing degradation of marketability in hardy kiwifruit during shelf life were decay and shriveling, whereas pitting and shriveling were the major physiological disorders in the fruits kept in cold storage. Fruit decay was negligible in the three cultivars kept in cold storage. The overall marketability of ‘Cheongsan’ fruit decreased by 32.0% after 3 weeks in cold storage because of fruit shriveling and pitting. The high incidence rate of decay and shriveling in ‘Cheongsan’ might have been influenced by rapid water loss and softening during shelf life and cold storage compared to ‘Daebo’ and ‘Daeseong’. ‘Daeseong’ might have been resistant to physiological disorders because it shows relatively persistent hardness during storage (Fig. 2). Thus, ‘Daeseong’ fruit were still considered marketable after 10 weeks in cold storage based on the low occurrence of physiological disorders.

Fig. 4.

Storage disorders, including decay (A and B), shriveling (C and D), and pitting (E and F), and overall marketability (G and H) in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit stored at 22°C for up to 7 d during shelf life (A, C, E, and G) and 2°C for up to 10 weeks during cold storage (B, D, F, and H). The levels of decay, shriveling, and pitting were evaluated on a five-point scale and scored as 0 = 0%, 1 = 1–10%, 2 = 11–25%, 3 = 26–50%, 4 = 51–75%, and 5 = 76–100% of the area of the fruit affected. Overall marketability of each cultivars was calculated as follows: 15 - (sum of the three index scores). Values represent the mean ± standard errors of replicates (n = 10).

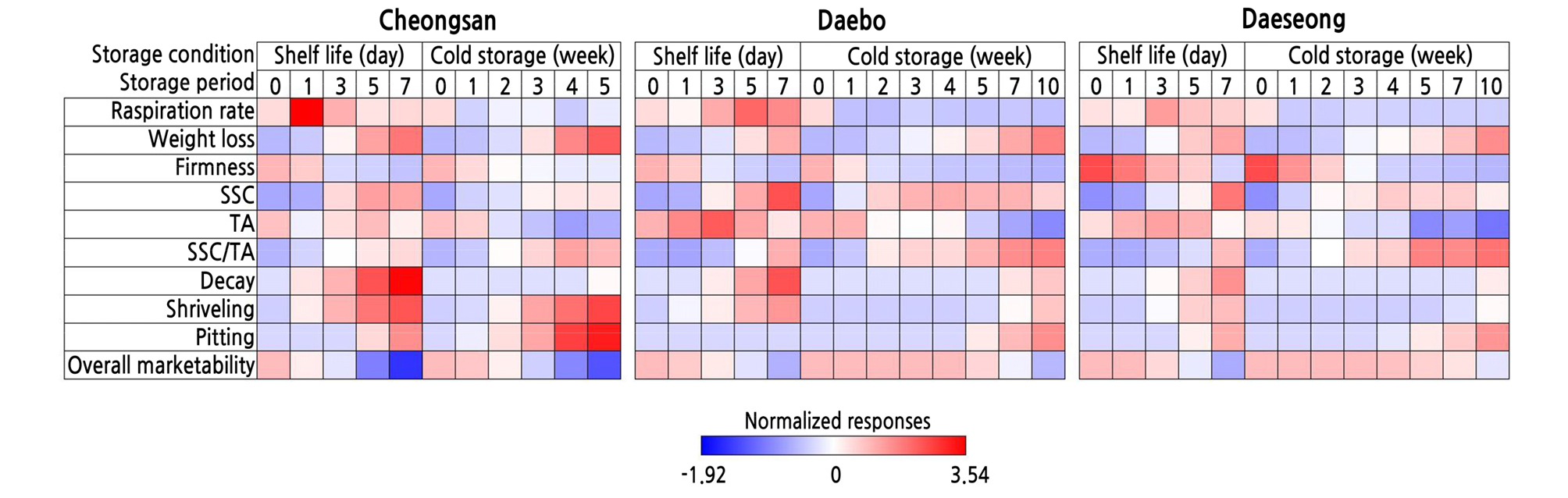

A heatmap provided overall responses of postharvest qualities in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit (Fig. 5). A color gradient from blue to red represented low levels ( ‑1.92) to high levels (3.54) of normalized responses. The normalized responses presented on the heatmap directly corresponded to the results of individual parameters in the fruits of the three cultivars in Figs. 2 to 4. The heatmap result indicated that ‘Cheongsan’ had relatively short storability based on its physiological disorders compared to ‘Daebo’ and ‘Daeseong’ fruit regardless of storage temperature.

Fig. 5.

Heatmap of postharvest qualities from ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit stored at 22°C for up to 7 d during shelf life and 2°C for up to 10 weeks during cold storage. The levels of storability correspond to the color scale. A color gradient from blue to red represents a low level to a high level of the normalized responses.

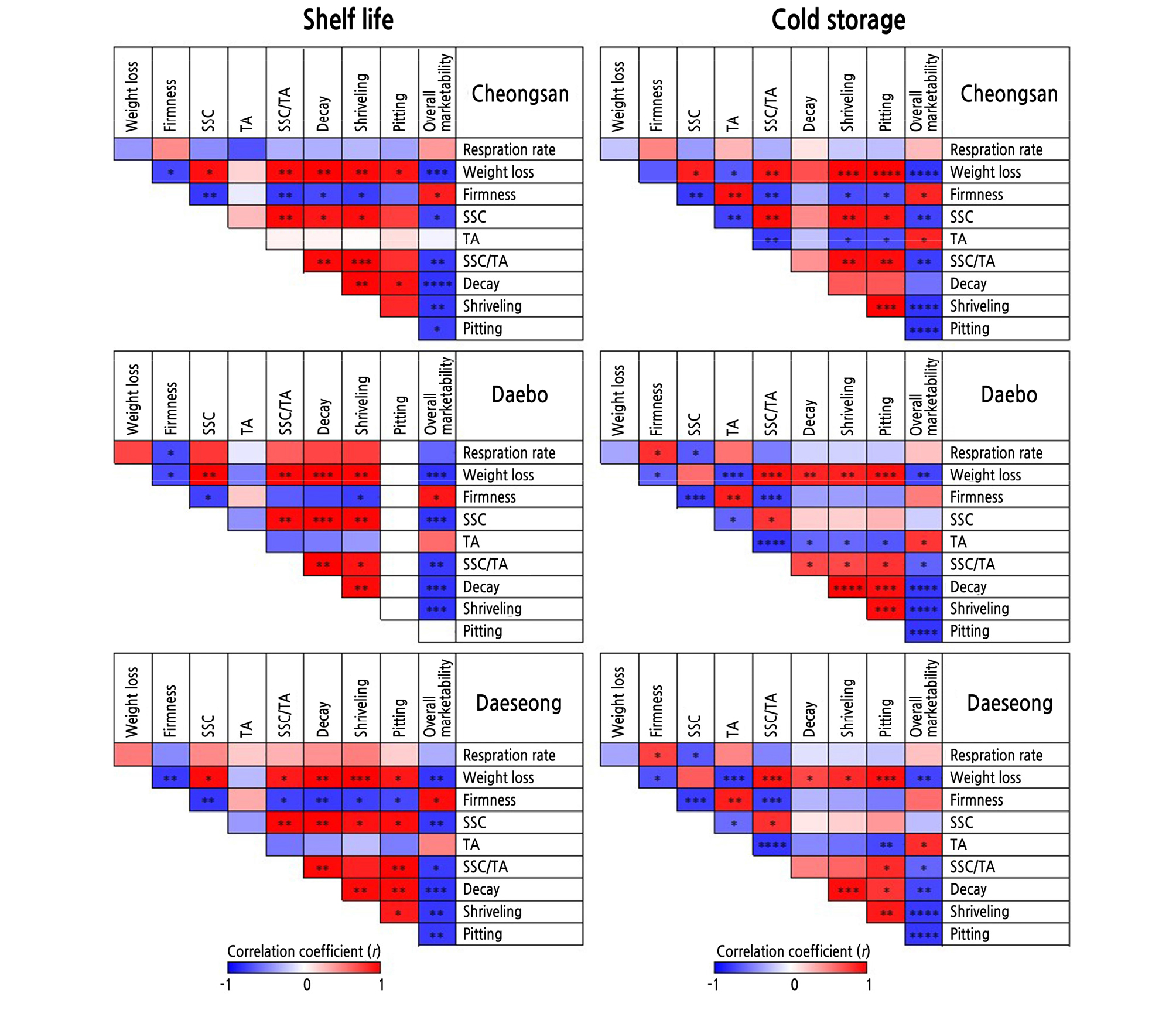

Pearson’s correlation coefficient analysis was performed to elucidate the relationship between individual parameters (Fig. 6). Blue and red colors indicated negative and positive correlations between individual parameters. Changes in hardy kiwifruit during shelf life in the three cultivars were strongly correlated with changes in weight loss, firmness, and SSC, whereas there was no statistically significant correlation with TA. Of the physiological disorders, decay, shriveling, and pitting were negatively correlated with marketability in ‘Cheongsan’ and ‘Daeseong’ during shelf life. The Pearson’s correlation coefficient analysis of the fruits stored in cold temperatures showed a similar pattern to those during shelf life, only differing in TA. TA levels were positively correlated with firmness and were negatively correlated with weight loss and SSC during cold storage. SSC was negatively linked with overall marketability of ‘Cheongsan’, but there was no statistically significant correlation between SSC and overall marketability in ‘Daebo’ and ‘Daeseong’ fruit during cold storage.

Fig. 6.

Pearson’s correlation coefficient (r) matrix from the postharvest qualities (respiration rate, weight loss, firmness, soluble solids content (SSC), titratable acidity (TA), ration of SSC to TA, decay, shriveling, pitting, and overall marketability) of ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit stored at 22°C for up to 7 d during shelf life and 2°C for up to 10 weeks during cold storage. Blue and red colors indicate negative and positive correlations between individual parameters. Asterisks (*, **, ***, and ****) indicate statistically significant correlations at p < 0.05, 0.01, 0.001, and 0.0001, respectively.

In this study, we investigated the postharvest quality in ‘Cheongsan’, ‘Daebo’, and ‘Daeseong’ hardy kiwifruit cultivars during shelf life and cold storage. As the fruits were after-ripened during storage, the fruits showed increases in SSC, decreases in firmness, and a deterioration of quality in the three cultivars, regardless of storage temperature. The marketability of the hardy kiwifruit during shelf life was mainly influenced by decay and shriveling, whereas pitting and shriveling were the major factors decreasing the marketability of fruit in cold storage. In general, ‘Cheongsan’ has relatively shorter storability than ‘Daebo’ and ‘Daeseong’ during both shelf life and cold storage. The overall marketability of ‘Cheongsan’ fruit declined greatly after 3 weeks in cold storage, but ‘Daeseong’ fruit were still marketable after 10 weeks in cold storage. Therefore, the results indicated that the postharvest quality was closely related to cultivar and storage temperature.